The membrane bioreactor (MBR) represents a significant advancement in wastewater treatment technology, combining biological treatment processes with membrane filtration. This integration results in a highly efficient and compact system capable of treating both municipal and industrial wastewater. The MBR technology has gained widespread acceptance due to its ability to produce high-quality effluent, which can be reused or safely discharged into the environment.

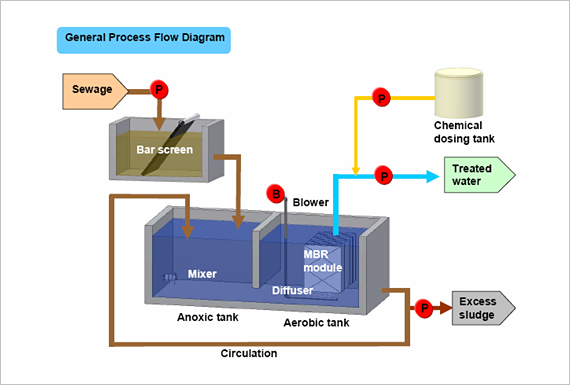

From an engineering standpoint, the MBR system consists of two main components: the biological reactor and the membrane filtration unit. The biological reactor is designed to facilitate the growth and activity of microorganisms that degrade organic matter present in the wastewater. The membrane filtration unit, typically comprising microfiltration or ultrafiltration membranes, serves to separate the treated water from the biomass and other suspended solids.

Biological Reactor: The biological reactor in an MBR system operates similarly to conventional activated sludge systems. Wastewater enters the reactor, where it is mixed with a concentrated suspension of microorganisms. These microorganisms metabolize the organic pollutants, converting them into carbon dioxide, water, and biomass. The reactor is aerated to provide the necessary oxygen for aerobic microbial activity and to maintain the suspension of the biomass.

Membrane Filtration Unit: The membrane filtration unit is integrated with the biological reactor. The membranes are typically submerged in the mixed liquor (a mixture of wastewater and biomass) or configured as an external loop. The membranes act as a physical barrier, allowing water molecules and dissolved substances to pass through while retaining the biomass and other suspended solids. This separation process ensures that the treated effluent is free from particulate matter and pathogens.

System Configuration: MBR systems can be configured in various ways, including submerged and side-stream configurations. In submerged MBRs, the membranes are immersed directly in the biological reactor, whereas in side-stream MBRs, the mixed liquor is pumped through external membrane modules. Each configuration has its advantages and is selected based on specific treatment requirements and operational considerations.

Biological Reactor: The biological reactor in an MBR system operates similarly to conventional activated sludge systems. Wastewater enters the reactor, where it is mixed with a concentrated suspension of microorganisms. These microorganisms metabolize the organic pollutants, converting them into carbon dioxide, water, and biomass. The reactor is aerated to provide the necessary oxygen for aerobic microbial activity and to maintain the suspension of the biomass.

Membrane Filtration Unit: The membrane filtration unit is integrated with the biological reactor. The membranes are typically submerged in the mixed liquor (a mixture of wastewater and biomass) or configured as an external loop. The membranes act as a physical barrier, allowing water molecules and dissolved substances to pass through while retaining the biomass and other suspended solids. This separation process ensures that the treated effluent is free from particulate matter and pathogens.

System Configuration: MBR systems can be configured in various ways, including submerged and side-stream configurations. In submerged MBRs, the membranes are immersed directly in the biological reactor, whereas in side-stream MBRs, the mixed liquor is pumped through external membrane modules. Each configuration has its advantages and is selected based on specific treatment requirements and operational considerations.

The scientific principles underlying the MBR process involve both biological and physical mechanisms. The biological degradation of organic pollutants is achieved through the metabolic activities of microorganisms, while the physical separation of treated water from biomass is accomplished using membrane filtration.

- Biological Degradation: The biological reactor in an MBR system provides an environment conducive to the growth and activity of a diverse microbial community. These microorganisms, including bacteria, protozoa, and fungi, utilize the organic pollutants in the wastewater as a source of carbon and energy. The metabolic pathways involved in the degradation process include aerobic respiration, nitrification, denitrification, and anaerobic digestion. The end products of these metabolic processes are carbon dioxide, water, and biomass.

- Membrane Filtration: The membrane filtration unit employs microfiltration or ultrafiltration membranes to achieve the physical separation of treated water from biomass. The membranes have pore sizes ranging from 0.1 to 0.01 micrometers, allowing water molecules and dissolved substances to pass through while retaining suspended solids, bacteria, and other pathogens. The filtration process is driven by a pressure gradient, with the treated water being drawn through the membranes by suction or positive pressure.

- Hybrid Mechanisms: The MBR process benefits from the synergistic effects of biological and physical mechanisms. The high biomass concentration in the reactor enhances the degradation of organic pollutants, while the membrane filtration ensures the production of high-quality effluent. Additionally, the retention of biomass within the reactor allows for longer solids retention times (SRT), which improves the stability and efficiency of the biological treatment process.

The MBR technology is employed in various water treatment applications, including municipal wastewater treatment, industrial wastewater treatment, and water reuse. Its ability to produce high-quality effluent makes it suitable for applications requiring stringent discharge standards and water reuse.

Municipal Wastewater Treatment: In municipal wastewater treatment, MBR systems are used to treat domestic sewage and produce effluent that meets regulatory standards for discharge into surface waters or for reuse in non-potable applications. The compact design of MBR systems allows for their installation in urban areas with limited space. The high removal efficiency of contaminants such as nitrogen, phosphorus, and pathogens ensures the protection of public health and the environment.

Industrial Wastewater Treatment: MBR systems are also used in industrial wastewater treatment to handle effluents from various industries, including food and beverage, pharmaceuticals, and textiles. The ability of MBR systems to treat high-strength wastewater and remove specific contaminants makes them suitable for industrial applications. The treated effluent can be reused within the industrial process or discharged safely into the environment.

Denitrification: In some activated sludge systems, anoxic zones are incorporated to facilitate denitrification, where nitrate is reduced to nitrogen gas by denitrifying bacteria in the absence of oxygen.

Water Reuse: The high-quality effluent produced by MBR systems is suitable for various water reuse applications, including irrigation, industrial processes, and groundwater recharge. The removal of pathogens and suspended solids ensures the safety and reliability of the reused water. MBR systems are increasingly being used in decentralized water reuse schemes, where treated wastewater is reused locally to reduce the demand for freshwater resources.

Municipal Wastewater Treatment: In municipal wastewater treatment, MBR systems are used to treat domestic sewage and produce effluent that meets regulatory standards for discharge into surface waters or for reuse in non-potable applications. The compact design of MBR systems allows for their installation in urban areas with limited space. The high removal efficiency of contaminants such as nitrogen, phosphorus, and pathogens ensures the protection of public health and the environment.

Industrial Wastewater Treatment: MBR systems are also used in industrial wastewater treatment to handle effluents from various industries, including food and beverage, pharmaceuticals, and textiles. The ability of MBR systems to treat high-strength wastewater and remove specific contaminants makes them suitable for industrial applications. The treated effluent can be reused within the industrial process or discharged safely into the environment.

Denitrification: In some activated sludge systems, anoxic zones are incorporated to facilitate denitrification, where nitrate is reduced to nitrogen gas by denitrifying bacteria in the absence of oxygen.

Water Reuse: The high-quality effluent produced by MBR systems is suitable for various water reuse applications, including irrigation, industrial processes, and groundwater recharge. The removal of pathogens and suspended solids ensures the safety and reliability of the reused water. MBR systems are increasingly being used in decentralized water reuse schemes, where treated wastewater is reused locally to reduce the demand for freshwater resources.

The implementation of MBR technology in water treatment provides numerous benefits, resulting in enhanced treatment efficiency, superior effluent quality, and increased operational flexibility.

High-Quality Effluent: The combination of biological treatment and membrane filtration in MBR systems results in the production of high-quality effluent with low concentrations of suspended solids, bacteria, and biochemical oxygen demand (BOD). This high-quality effluent can be discharged into sensitive receiving waters or reused for various applications.

Compact Design: MBR systems have a smaller footprint, making them suitable for installation in areas with limited space. The high biomass concentration and efficient separation process allow for the use of smaller bioreactors and membrane modules.

Operational Flexibility: MBR systems offer greater operational flexibility. The ability to maintain high biomass concentrations and longer solids retention times (SRT) allows for better control of the biological treatment process. Additionally, the modular design of membrane units facilitates easy maintenance and scalability.

Enhanced Nutrient Removal: MBR systems can achieve enhanced nutrient removal, including nitrogen and phosphorus. The high biomass concentration and longer SRT provide favorable conditions for nitrification and denitrification processes, resulting in the effective removal of nitrogen compounds. Phosphorus removal can be achieved through biological uptake or chemical precipitation.

Reduced Sludge Production: The longer solids retention times (SRT) in MBR systems result in reduced sludge production. The lower sludge production reduces the need for sludge handling and disposal, leading to cost savings and environmental benefits.

Automation and Control: MBR systems are highly amenable to automation and control, allowing for real-time monitoring and optimization of the treatment process. Advanced control systems can be implemented to adjust operational parameters, such as aeration rates and membrane flux, based on real-time data. This automation enhances the efficiency and reliability of the treatment process.

.gif)