The multiple effect evaporator (MEE) is a sophisticated apparatus employed in various industrial processes, including water treatment. This technology is designed to efficiently utilize the heat from steam to evaporate water, thereby concentrating solutions and reducing the volume of waste. The MEE system is particularly advantageous in scenarios where large volumes of water need to be evaporated, such as in desalination, wastewater treatment, and the production of liquid concentrates.

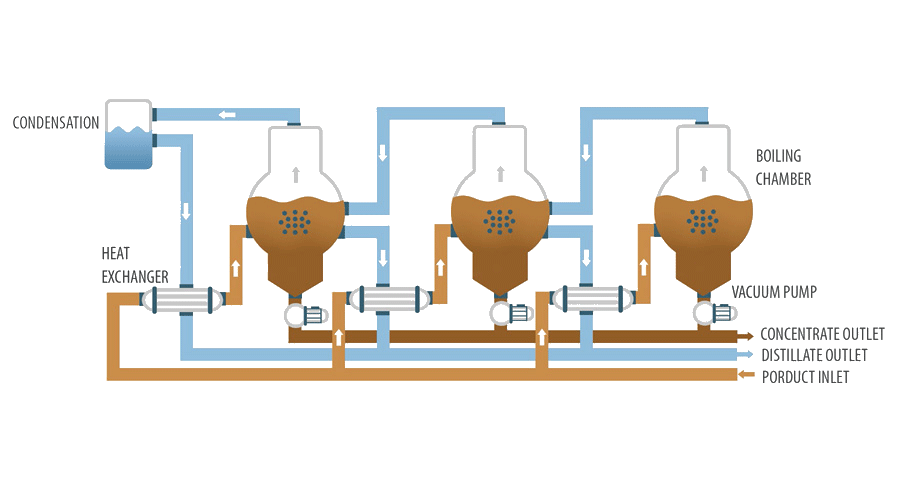

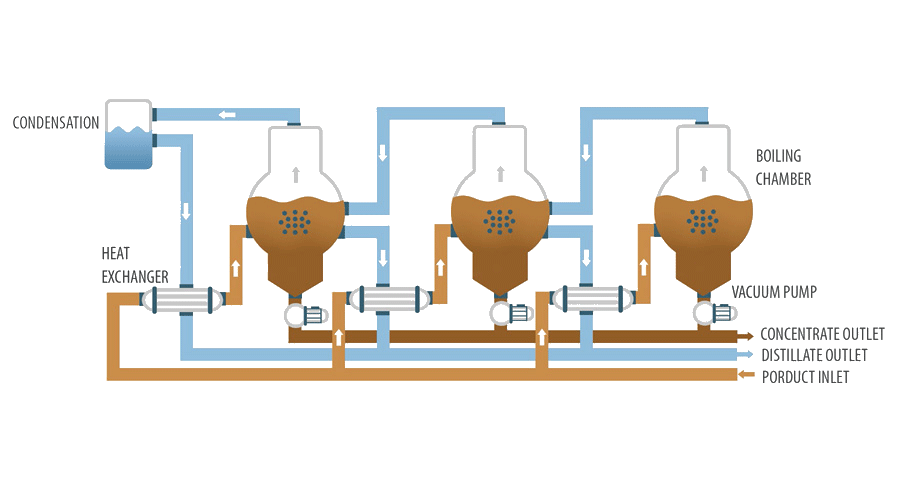

From an engineering standpoint, the multiple-effect evaporator operates on the principle of using the vapor generated from one effect to heat the subsequent effect. This cascading use of vapor significantly enhances the thermal efficiency of the system. The MEE typically consists of several stages or effects, each maintained at a progressively lower pressure and temperature. The primary components of an MEE include:

Evaporator Bodies: These are the vessels where the evaporation process occurs. Each body is equipped with a heating section and a vapor-liquid separation section.

Heat Exchangers: These facilitate the transfer of heat from the steam to the liquid being evaporated.

Condensers: These are used to condense the vapor generated in the final effect.

Pumps and Piping: These components are essential for the circulation of the liquid and vapor between the different effects.

Evaporator Bodies: These are the vessels where the evaporation process occurs. Each body is equipped with a heating section and a vapor-liquid separation section.

Heat Exchangers: These facilitate the transfer of heat from the steam to the liquid being evaporated.

Condensers: These are used to condense the vapor generated in the final effect.

Pumps and Piping: These components are essential for the circulation of the liquid and vapor between the different effects.

The process begins with the introduction of the feed solution into the first effect, where it is heated by steam. The vapor generated in the first effect is then used to heat the second effect, and this process continues through all subsequent effects. The final product is a concentrated solution, and the vapor from the last effect is condensed and often reused.

The scientific principle underlying the operation of a multiple-effect evaporator is based on the thermodynamic properties of water and steam. The key concepts include:

Boiling Point Elevation: As the pressure decreases in each subsequent effect, the boiling point of the solution also decreases. This allows the vapor from one effect to be used as the heating medium for the next effect.

Latent Heat of Vaporization: The energy required to convert water from liquid to vapor is utilized efficiently by reusing the vapor in multiple stages

Heat Transfer: Efficient heat transfer is crucial for the operation of an MEE. The heat exchangers are designed to maximize the transfer of heat from the steam to the liquid.

Sedimentation: The flocs, being larger and heavier than the individual particles, settle to the bottom of the sedimentation basin. The rate of sedimentation is influenced by the size and density of the flocs, as well as the viscosity of the water.

The process can be described by the following steps:

Feed Preheating: The feed solution is preheated using the condensate from the final effect to improve overall efficiency.

Evaporation: In each effect, the feed solution is heated to its boiling point, and water is evaporated.

Vapor Compression: The vapor generated in each effect is compressed and used to heat the next effect.

Condensation: The vapor from the final effect is condensed, and the condensate is often reused in the process.

Application in Water Treatment

In the context of water treatment, multiple-effect evaporators are used to concentrate wastewater, reduce its volume, and recover valuable by-products. The primary applications include:

Desalination: MEEs are used to remove salts and other impurities from seawater or brackish water, producing fresh water and concentrated brine.

Wastewater Treatment: Industrial wastewater often contains high concentrations of dissolved solids. MEEs can concentrate these solids, reducing the volume of waste and facilitating easier disposal or further treatment.

Zero Liquid Discharge (ZLD) Systems: In ZLD systems, MEEs are used to evaporate all the water from the wastewater, leaving behind solid residues. This process ensures that no liquid waste is discharged into the environment.

Advantages of Multiple Effect Evaporators

The use of multiple-effect evaporators in water treatment offers several advantages:

Energy Efficiency: By reusing the vapor generated in each effect, MEEs significantly reduce the overall energy consumption compared to single-effect evaporators.

Cost-Effectiveness: The reduced energy consumption translates into lower operational costs, making MEEs an economically viable option for large-scale water treatment.

Scalability: MEEs can be designed with multiple effects to handle varying volumes of wastewater, making them suitable for both small and large-scale operations.

Environmental Benefits: The ability to concentrate and reduce the volume of wastewater minimizes the environmental impact of industrial processes.

.gif)