Micro/nano ozone systems are advanced water treatment technologies that utilize micro and nanobubbles of ozone to significantly enhance the efficiency of water and wastewater treatment processes. This innovative approach is designed to maximize the contact and reaction between ozone and contaminants, leading to superior treatment performance.

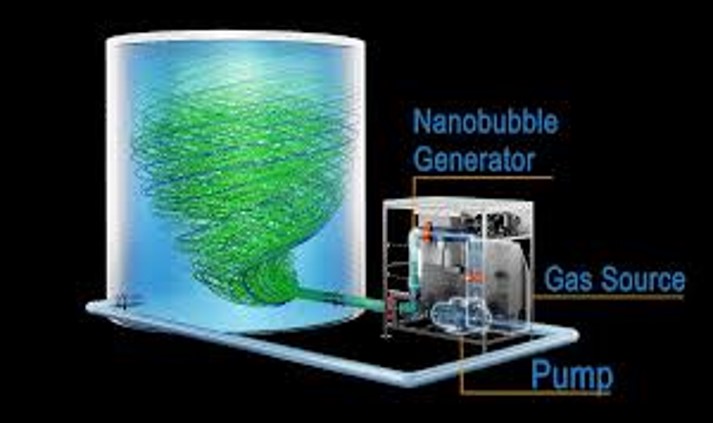

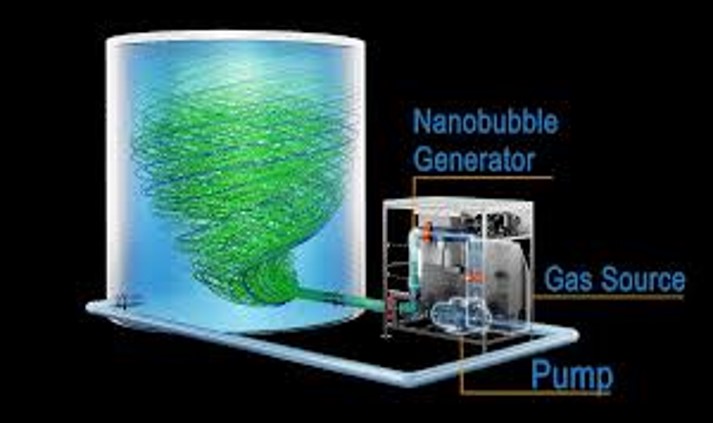

From an engineering standpoint, micro/nano ozone systems are designed to achieve high efficiency in water treatment. The primary components of a micro/nano ozone system include:

Ozone Generator: Produces ozone gas from oxygen, using either electrical discharge or UV light methods, to ensure a high concentration of ozone for effective treatment.

Micro/Nanobubble Generator: Injects ozone gas into water, forming micro and nanobubbles that enhance the dissolution of ozone and improve contact with contaminants.

Contact Tank: Provides an environment for the ozone micro/nanobubbles to interact with and oxidize contaminants effectively.

Diffusers and Mixers: Ensure uniform distribution and dispersion of the micro/nanobubbles throughout the water, enhancing the overall treatment process.

Control System: Monitors and regulates key parameters such as ozone concentration, bubble size, and contact time to maintain optimal performance and efficiency.

There are several essential processes within micro/nano ozone systems that contribute to their high efficiency and effectiveness in water treatment. Here's an overview of these key processes:

Ozone Generation: Ozone gas (O3) is generated from oxygen (O2) using an ozone generator. This process typically involves the conversion of oxygen molecules into ozone molecules through electrical discharge or ultraviolet (UV) light.

Micro/Nano Bubble Formation: The generated ozone gas is injected into water via micro/nanobubble generators. These generators create extremely small bubbles, ranging from tens of nanometers to several micrometers in size, significantly enhancing the dissolution of ozone into water.

Enhanced Contact: The small size of the micro/nanobubbles provides a large surface area, which facilitates better gas-liquid contact and mass transfer between the ozone and contaminants.

Oxidation Process: The ozone within the micro/nanobubbles reacts with contaminants in the water, leading to the oxidation and breakdown of organic and inorganic pollutants.

Dissolution and Reaction: As the ozone in the micro/nanobubbles dissolves into the water, it continues to react with any remaining contaminants, ensuring thorough treatment.

Applications

Micro/nano ozone systems are suitable for a wide range of applications, including:

Municipal Wastewater Treatment: Effective in removing contaminants and pathogens from municipal wastewater.

Industrial Wastewater Treatment: Ideal for treating complex industrial effluents containing organic and inorganic pollutants.

Drinking Water Treatment: Enhances the quality and safety of drinking water by eliminating harmful microorganisms and chemical residues.

Agricultural Runoff Treatment: Reduces the impact of pesticides and nutrients in agricultural runoff, protecting water bodies.

Improvement of Water Treatment Processes

High Efficiency: The large surface area of micro/nanobubbles ensures efficient ozone dissolution and contaminant oxidation.

Improved Disinfection: Effective in killing bacteria, viruses, and other pathogens.

Organic Matter Degradation: Breaks down complex organic compounds, including pharmaceuticals and pesticides.

Taste and Odor Control: Eliminates taste and odor-causing compounds, improving water quality.

Environmental Friendly: Ozone decomposes into oxygen, leaving no harmful residues.

.gif)