Reverse osmosis (RO) is a widely utilized water purification technology that employs a semi-permeable membrane to remove ions, molecules, and larger particles from drinking water. This process is essential in various applications, including desalination, wastewater treatment, and the production of potable water. The following sections will provide a comprehensive explanation of reverse osmosis from an engineering perspective, a scientific method of action perspective, and its application in water treatment processes.

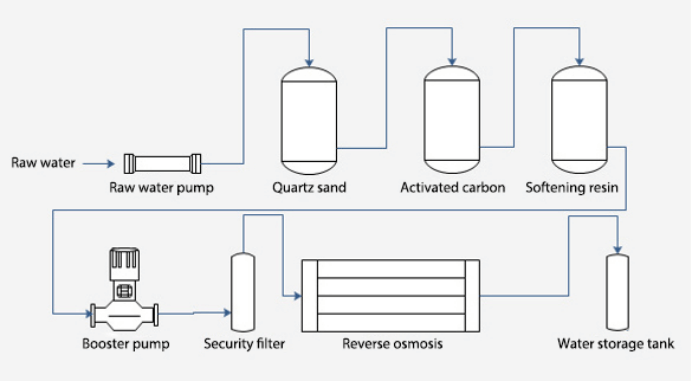

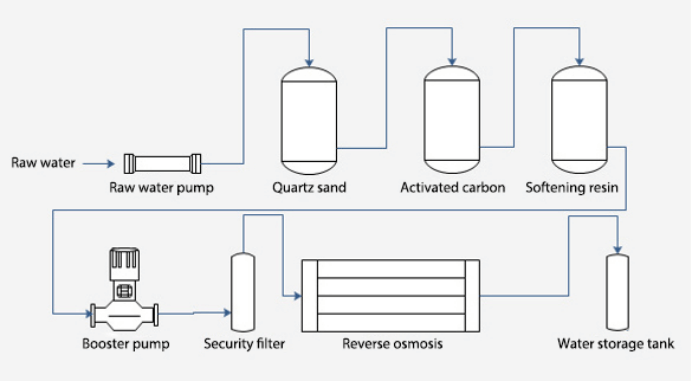

From an engineering standpoint, reverse osmosis systems are designed to achieve high efficiency in water purification. The primary components of an RO system include:

Pre-treatment Units: These units are responsible for removing larger particles and contaminants that could damage the RO membrane. Pre-treatment typically involves sediment filters, activated carbon filters, and sometimes anti-scalant dosing to prevent membrane fouling.

High-Pressure Pump: The high-pressure pump is crucial as it provides the necessary pressure to overcome the natural osmotic pressure and force water through the semi-permeable membrane. The pressure required depends on the salinity of the feed water, with seawater requiring higher pressures compared to brackish water.

RO Membrane: The semi-permeable membrane is the core component of the RO system. It allows water molecules to pass through while rejecting dissolved salts, organic molecules, and other impurities. The membrane is typically made of thin-film composite (TFC) material, which offers high rejection rates and durability.

Post-treatment Units: After the water passes through the RO membrane, it may undergo post-treatment to adjust pH levels, add minerals for taste, or further purify the water. This stage ensures the water meets the desired quality standards.

Storage and Distribution: The purified water is stored in tanks and then distributed for use. In large-scale applications, such as municipal water treatment plants, the distribution system includes pipelines and pumps to deliver water to consumers.

The scientific principle behind reverse osmosis is based on the natural process of osmosis. Osmosis is the movement of water molecules from a region of lower solute concentration to a region of higher solute concentration through a semi-permeable membrane. This process continues until equilibrium is reached, with equal concentrations on both sides of the membrane.

In reverse osmosis, this natural process is reversed by applying external pressure to the concentrated solution. The applied pressure must exceed the osmotic pressure to force water molecules to move from the concentrated solution to the dilute solution, leaving behind the dissolved solutes. The key steps in the RO process are as follows:

Feed Water Introduction: The feed water, containing dissolved salts and impurities, is introduced into the RO system.

Pressure Application: A high-pressure pump applies pressure to the feed water, forcing it through the semi-permeable membrane.

Membrane Separation: As the water passes through the membrane, the semi-permeable nature of the membrane allows only water molecules to pass, while rejecting larger molecules and ions.

Permeate and Concentrate Streams: The purified water that passes through the membrane is called the permeate, while the concentrated solution containing the rejected impurities is called the concentrate or brine.

Collection and Disposal: The permeate is collected for use, while the concentrate is typically disposed of or treated further, depending on environmental regulations and the specific application.

Application in Water Treatment

Reverse osmosis is employed in various water treatment applications due to its effectiveness in removing a wide range of contaminants. Some of the key applications include:

Reverse osmosis is employed in various water treatment applications due to its effectiveness in removing a wide range of contaminants. Some of the key applications include:

Desalination: RO is extensively used for desalination, the process of removing salts and minerals from seawater to produce potable water. This application is critical in regions with limited freshwater resources, such as the Middle East and coastal areas.

Wastewater Treatment: RO is used in wastewater treatment plants to remove contaminants and produce high-quality effluent that can be reused or safely discharged into the environment. This application helps in reducing the environmental impact of industrial and municipal wastewater.

Drinking Water Purification: RO systems are commonly used in residential and commercial settings to provide clean drinking water. These systems remove impurities such as heavy metals, pesticides, and microorganisms, ensuring safe and healthy water for consumption.

Industrial Applications: In industries such as pharmaceuticals, food and beverage, and electronics, RO is used to produce high-purity water required for various processes. The removal of dissolved ions and organic compounds is essential to meet stringent quality standards in these industries.

Improvement of Water Treatment Processes

Reverse osmosis technology significantly improves water treatment processes by offering several advantages:

High Contaminant Removal Efficiency: RO systems can remove up to 99% of dissolved salts, organic compounds, and other impurities, providing high-quality water that meets stringent standards.

Versatility: RO can be applied to various types of feed water, including seawater, brackish water, and wastewater, making it a versatile solution for different water treatment needs.

Scalability: RO systems can be scaled to meet the requirements of small residential units or large municipal water treatment plants, offering flexibility in design and implementation.

Energy Efficiency: Advances in membrane technology and energy recovery systems have made RO more energy-efficient, reducing operational costs and environmental impact.

Minimal Chemical Use: Unlike some other water treatment methods, RO relies primarily on physical separation rather than chemical reactions, reducing the need for chemical additives and minimizing the risk of chemical contamination.

.gif)