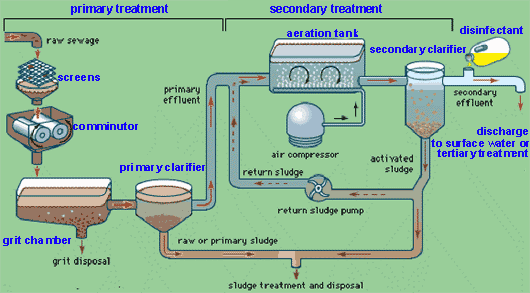

The activated sludge process is a cornerstone of modern wastewater treatment, widely employed to treat both municipal and industrial wastewater. This process leverages the natural biological activity of microorganisms to degrade organic pollutants, producing a high-quality effluent suitable for discharge or further treatment. The activated sludge process consists of several key components, each playing a crucial role in the overall treatment system:

Aeration Tank: This is the heart of the activated sludge process. Wastewater is mixed with a microbial culture (activated sludge) and aerated to promote the growth and activity of aerobic microorganisms. The aeration tank is designed to provide sufficient oxygen and mixing to maintain the organisms in suspension and ensure efficient contact with the organic pollutants.

Aeration System: Various aeration methods are employed, including diffused aeration, surface aerators, and mechanical aerators. Diffused aeration involves the use of fine or coarse bubble diffusers to introduce air or oxygen into the wastewater. Surface aerators, on the other hand, agitate the water surface to promote oxygen transfer

Secondary Clarifier: After aeration, the mixed liquor (a mixture of wastewater and activated sludge) flows into a secondary clarifier. Here, the biological flocs (sludge) settle to the bottom, separating the treated effluent from the sludge. The clarified effluent is then discharged or subjected to further treatment.

Return Activated Sludge (RAS) System: A portion of the settled sludge from the secondary clarifier is returned to the aeration tank to maintain the desired concentration of microorganisms. This is known as return-activated sludge (RAS). The remaining sludge (waste-activated sludge also known as WAS) is removed from the system for further treatment and disposal.

Control Systems: Modern activated sludge systems are equipped with advanced control systems that monitor and regulate key parameters such as dissolved oxygen levels, sludge age, and hydraulic retention time. These control systems ensure the treatment process's optimal performance and stability.

There are a few parameters to be considered in the design of an activated sludge process, mainly:

Hydraulic Retention Time (HRT): The wastewater spends time in the aeration tank, designed based on its characteristics and the desired treatment level.

Solid Residence Time (SRT) or Sludge Age: The average time microorganisms spend in the system, is crucial for microbial growth and activity.

Mixed Liquor Suspended Solids (MLSS): This is the concentration of suspended solids in the aeration tank, including microorganisms and the organic matter they degrade.

Dissolved Oxygen (DO): Adequate dissolved oxygen levels are essential for aerobic microorganisms to thrive.

The Method of action of the activated sludge process depends on the metabolic activity of a diverse community of microorganisms, primarily bacteria, to degrade organic pollutants. This process can be explained using 4 main reactions.

Aerobic Oxidation: In the presence of oxygen, aerobic bacteria oxidize organic matter (carbonaceous pollutants) to carbon dioxide, water, and new biomass.

Nitrification: Ammonia and other nitrogenous compounds present in the wastewater are oxidized to nitrate by nitrifying bacteria

Denitrification: In some activated sludge systems, anoxic zones are incorporated to facilitate denitrification, where nitrate is reduced to nitrogen gas by denitrifying bacteria in the absence of oxygen.

Phosphorus Removal: Certain microorganisms, known as polyphosphate-accumulating organisms (PAOs), can uptake and store excess phosphorus from the wastewater. This process is enhanced by alternating aerobic and anaerobic conditions.

After the reactions are deemed to have been completed the process undergoes flocculation and settling where the microorganisms in the activated sludge form flocs, which are aggregates of bacteria, protozoa, and other microorganisms. These flocs have a higher settling velocity than individual cells, allowing them to settle efficiently in the secondary clarifier. The settling process is influenced by factors such as floc size, density, and the presence of filamentous bacteria, which can cause sludge bulking and poor settling.

Treatment of Municipal and Industrial Wastewater

The activated sludge process is widely used to treat municipal and industrial wastewater. It is particularly effective in removing biodegradable organic matter, nitrogen, and phosphorus from the wastewater. The process can be adapted to handle a wide range of wastewater characteristics and treatment requirements.

Municipal Wastewater Treatment: In municipal wastewater treatment plants, the activated sludge process is used to treat domestic sewage, which contains a high concentration of organic matter and nutrients. The process produces a high-quality effluent that meets stringent discharge standards.

Industrial Wastewater Treatment: The activated sludge process is also employed in various industrial sectors, including food and beverage, pharmaceuticals, and chemical manufacturing. Industrial wastewater often contains complex organic compounds and toxic substances, which can be effectively degraded by the diverse microbial community in the activated sludge.

The activated sludge process is highly valued for its efficiency and effectiveness in treating wastewater. It enhances the removal of organic matter and nutrients, leading to cleaner effluent and improved environmental protection. Some of the benefits of using the activated sludge process are:

High Treatment Efficiency: The process is highly efficient in removing organic matter, nitrogen, and phosphorus from the wastewater, producing a high-quality effluent.

Flexibility and Adaptability: The process can easily handle varying wastewater characteristics and treatment requirements. It can be modified to include additional treatment steps such as nitrification, denitrification, and phosphorus removal.

Compact Footprint: The activated sludge process requires relatively less space than other treatment methods, making it suitable for urban and industrial settings with limited land availability.

Cost-Effectiveness: The process is cost-effective in terms of both capital and operational costs. Biological treatment reduces the need for expensive chemical additives.

Sustainability: The activated sludge process is environmentally sustainable, relying on natural biological processes to degrade pollutants. It also produces a valuable byproduct, waste-activated sludge, which can be further treated and used as a soil conditioner or for energy recovery.

.gif)