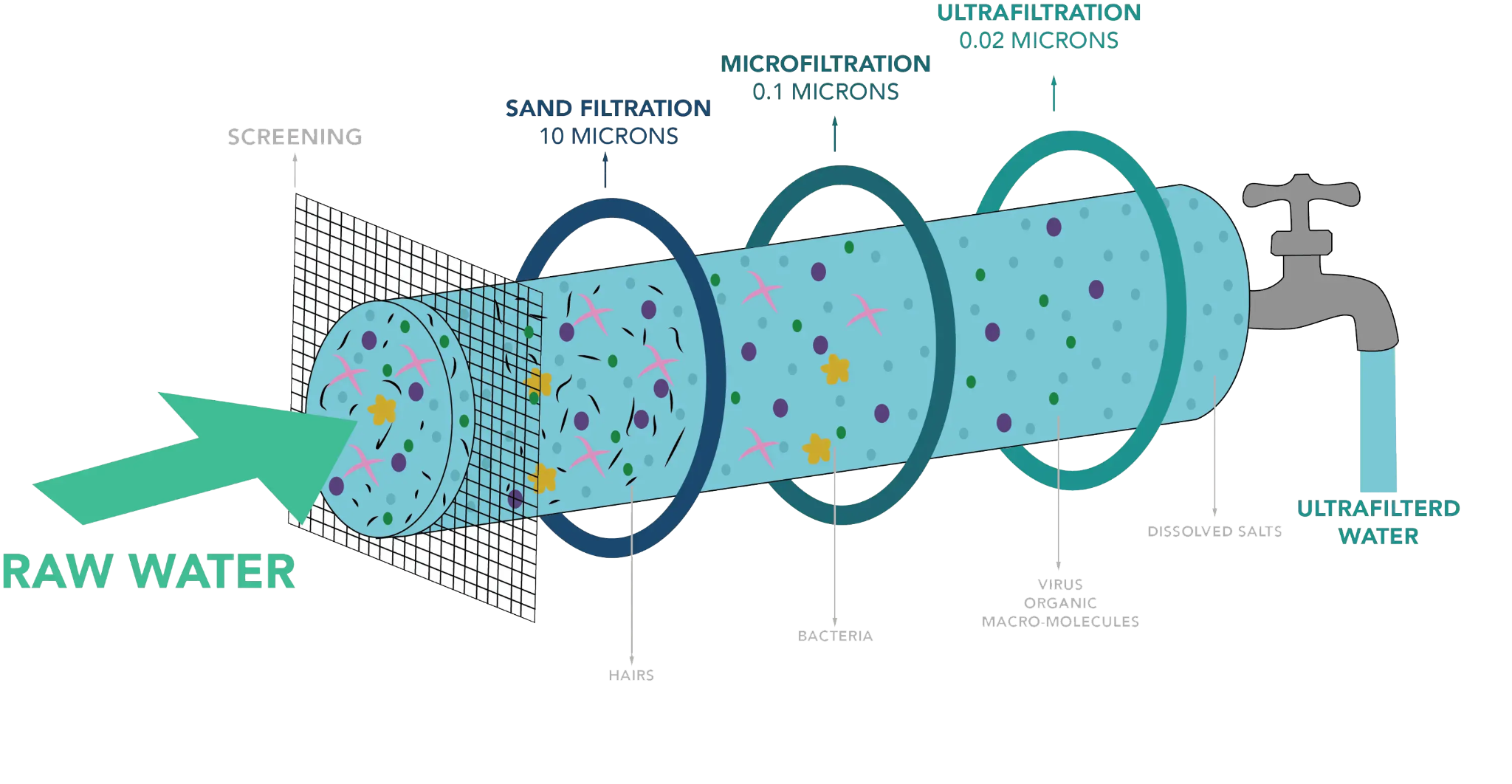

Ultrafiltration (UF) is a membrane filtration process that is widely employed in water treatment to remove particulates and macromolecules from raw water. This technology is characterized by its ability to filter out contaminants based on size exclusion, utilizing a semipermeable membrane. The process is highly effective in producing potable water and is often used in conjunction with other water treatment methods to enhance overall efficiency and water quality.

From an engineering standpoint, ultrafiltration systems are designed to operate under pressure, forcing water through a semipermeable membrane. The system typically consists of several key components:

- Feed Pump: This component is responsible for supplying raw water to the ultrafiltration unit at the required pressure.

- Membrane Modules: These are the core of the UF system, containing the semipermeable membranes through which water is filtered.

- Pressure Vessels: These vessels house the membrane modules and maintain the necessary pressure for filtration.

- Control Systems: Automated control systems are used to monitor and regulate the operation of the UF system, ensuring optimal performance and efficiency.

- Cleaning Systems: Periodic cleaning of the membranes is essential to prevent fouling and maintain performance. Cleaning systems typically use chemical agents to remove accumulated contaminants.

The engineering design of UF systems focuses on optimizing the flow dynamics, pressure distribution, and membrane configuration to achieve maximum filtration efficiency. The membranes are often arranged in a cross-flow configuration, where the feed water flows tangentially across the membrane surface, reducing the buildup of contaminants and extending the membrane’s lifespan.

The ultrafiltration process operates based on the principle of size exclusion. The semipermeable membranes used in UF have pore sizes ranging from 0.01 to 0.1 microns, allowing water and low-molecular-weight solutes to pass through while retaining larger particles and macromolecules. The separation mechanism can be described as follows:

The effectiveness of ultrafiltration is influenced by several factors, including membrane material, pore size distribution, feed water quality, and operating conditions. Common membrane materials include polymers such as polyethersulfone (PES), polyvinylidene fluoride (PVDF), and cellulose acetate. These materials are selected for their chemical resistance, mechanical strength, and ability to achieve high filtration rates.

Application in Water Treatment

Ultrafiltration offers several advantages over traditional water treatment methods:

.gif)